FASTENER SUPERSTORE

FASTENER GUIDE

Screws - Thread Styles

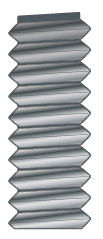

Machine Screw / Cap Screw Threads are used in numerous types of screws and bolts:

Most commonly referred to as machine screw threads, screws of this style are designed to align with a threaded nut or hole with a matching diameter and thread count. They use Unified Thread Standard (UTS), and are generally available in UNC (Unified National Coarse) and UNF (Unified National Fine) options. Sizes below 1/4" use numbers to describe their diameter, while screws 1/4" and higher use fractions. Their sizes are described first with the diameter, followed by a hyphen, and then with the count of threads per inch. (Examples: 4-40, 12-24, 5/16-18)

Metric Machine Screws are notated in metric diameter and thread pitch. Pitch is the distance, in millimeters, between threads.

Below are the metric screw and bolt sizes that we carry:

| M1.6-0.35 | M2-0.4 | M2.5-0.45 | M3-0.5 | M3.5-0.6 |

| M4-0.7 | M5-0.8 | M6-1.0 | M7-1.0 | M8-1.25 |

| M10-1.5 | M12-1.75 | M14-2.0 | M16-2.0 | M18-2.5 |

| M20-2.5 | M24-3.0 |

| Screw Size | UNC | UNF |

| #0 | 0-80 | |

| #1 | 1-64 | 1-72 |

| #2 | 2-56 | 2-64 |

| #3 | 3-48 | 3-56 |

| #4 | 4-40 | 4-48 |

| #5 | 5-40 | 5-44 |

| #6 | 6-32 | 6-40 |

| #8 | 8-32 | 8-36 |

| #10 | 10-24 | 10-32 |

| #12 | 12-24 | |

| 1/4" | 1/4-20 | 1/4-28 |

| 5/16" | 5/16-18 | 5/16-24 |

| 3/8" | 3/8-16 | 3/8-24 |

| 7/16" | 7/16-14 | 7/16-20 |

| 1/2" | 1/2-13 | 1/2-20 |

| 9/16" | 9/16-12 | 9/16-18 |

| 5/8" | 5/8-11 | 5/8-18 |

| 3/4" | 3/4-10 | 3/4-16 |

| 7/8" | 7/8-9 | 7/8-14 |

| 1" | 1-8 | 1-14 |

| 1 1/8" | 1 1/8-7 | 1 1/8-12 |

| 1 1/4" | 1 1/4-7 | 1 1/4-12 |

| 1 3/8" | 1 3/8-6 | 1 3/8-12 |

| 1 1/2" | 1 1/2-6 | 1 1/2-12 |

| 1 3/4" | 1 3/4-5 | |

| 2" | 2-4.5 | |

| 2 1/4" | 2 1/4-4.5 | |

| 2 1/2" | 2 1/2-4 | |

| 2 3/4" | 2 3/4-4 | |

| 3" | 3-4 | |

| 3 1/4" | 3 1/4-4 | |

| 3 1/2" | 3 1/2-4 | |

| 3 3/4" | 3 3/4-4 | |

| 4" | 4-4 |

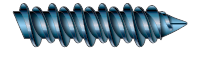

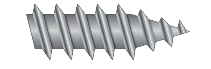

Concrete

Screws

Concrete screws cut their own threads into concrete, brick and other masonry materials. Features high and low double lead threads with notched high threads. Diamond shaped, nail point helps with self starting in hard, dense material.

Deck

Screws

Used in woods with medium density. Dacrotized steel provides corrosion resistance and doesn't discolor wood. Stainless steel options are also offered in a type 17 point which has a chip cavity to assist with driving.

Drywall

Screws

Coarse Drywall Screws feature an extra sharp point, spaced threads and a black phosphate finish. Fine Drywall Screws have double lead threads for easy self starting. We also carry drywall screws in High-Low and Self-Drilling styles.

Lag

Screws

Featuring a hex head, widely spaced threads and a gimlet point, lag screws are most commonly used in wood or with lag screw shields. Larger diameters generally require pre-drilled pilot holes.

Self-Drilling

Screws

Used in thin metals, often metal roofing for barns and other outbuildings. The sharp tip allows for self starting without drilling pilot holes, while the twin lead threads reduce driving torque.

Sheet Metal/

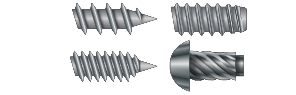

Self Tapping Screws

Most screws with pointed tips can fall under the "self tapping" name, but at Fastener SuperStore we categorize self drilling and self tapping as separate styles. The first two of the four styles in our "Self Tapping" section, and are often referred to as sheet metal screws.

Type A - Widely spaced threads and always fully threaded, these screws have the same thread counts as standard wood screws. The only difference being that wood screws are partially threaded.

Type AB - Features finer threads for better hold in thin sheet metal. Recommended over type A for resin filled plywood and other brittle materials.

Type B - Blunt point requires pre-drilling. For molded or through holes in thin metal, nonferrous castings, plastics or resin-filled plywood.

U Drive - Rounded head, not containing a drive style, U drive screws are also called hammer drive screws. They are hammered into predrilled holes in metals and plastics, creating a permanent fastening.

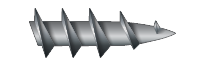

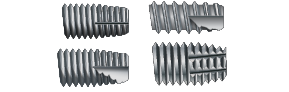

Thread Cutting

Screws

These styles of screws cut matching threads into the materials into which they are installed. Sharp cutting edges assist with driving, while a variety of chip cavity styles help with clearance of cut materials.

Type 1 - Generally used in softer metals such as steel sheets, alloy steels, cast iron, brass and plastics. Has machine screw threads.

Type 23 - These thread cutting screws feature machine screw threads, a blunt point and a large chip cavity. The cavity allows for clearance of the cut material.

Type 25 - Features wider spaced threads than other thread cutting screws, a blunt point and a large chip cavity. For molded or through holes in plastics and other soft materials

Type F - Machine screw threads, a blunt point and multiple cutting edges, these screws are used in heavy gauge sheet metal, aluminum, zinc and lead die castings, cast iron, brass and plastics.

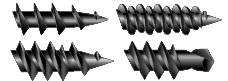

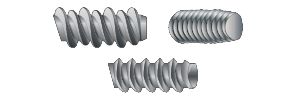

Thread Forming/

Thread Rolling Screws

Rather than cutting threads into materials, thread forming screws create threads by compacting and creating pressure against the walls of the materials it is installed into.

High - Low - Used in softer materials such as plastic, nylon and wood. Double lead thread design reduces torque requirements, improves pullout strength and lessens the risk of damaging or cracking materials.

Trilobe TFS for Metal - Generic alternatives to TAPTITE® screws, trilobular design allows for lower driving torque, eliminates chips and resists vibrational loosening.

TFS for Plastics - Generic alternatives to PLASTITE® screws, they also feature a trilobular design with widely spaced threads, offers easy starting into predrilled holes. Used in plastics and other soft materials.

Type 17

Thread cutting style offered in combination with some deck and wood screws. Wide, sharp chip cavity helps with clearance of materials. Widely spaced, sharp threads help lower driving torque requirements.

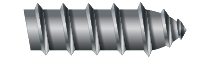

Wood

Screws

Designed with a tapered point, and a sharp crested, coarse pitch thread, they are able to self start in wood materials. Produces a mating thread which assists with pullout strength.

FASTENER BUYING MADE SIMPLE

The Fastener Superstore is your one stop shop for screws, nuts, bolts, washers, rivets, standoffs and more! We have everything you need right here.

- 34,000+ Distinct Parts

- All Pricing Online

- Order online, via phone, email or fax

- Extended Customer Service Hours (7am-7pm CT)

- Quotes Available for Larger Quantities

TAPTITE® and PLASTITE® are registered trademarks owned by Research Engineering & Manufacturing, Inc. (REMINC). REMINC has not licensed the use of either of these trademarks to Fastener SuperStore.